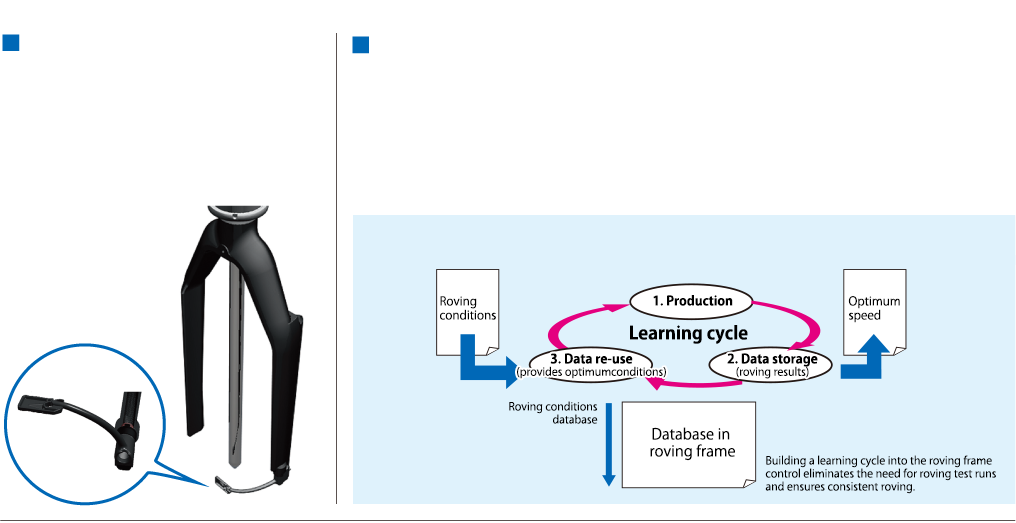

Learning function eliminates roving test runs and ensures consistent roving packages.

To maintain optimum output quality in highspeed operation, the FL200 uses a flyer designed especially for high-speed performance. An internal stainless steel tubular roving guide connecting directly to the presser protects against the adverse effects of air turbulence, dust, and fly in high-speed production. As a result, the FL200 operates dependably at speeds up to 1,500 rpm.

A test run is normally required when roving new yarn types and yarn counts to determine the amount of increase in the bobbin diameter and input to the roving frame. The FL200 has completely eliminated this troublesome operation: in addition to an automatic calculation function for bobbin diameter increase based on the database inherited from the FL100, we have added a new control feature that successively predicts and corrects the actual amount of increase in bobbin diameter based on continuously accumulated operational data. As a result, actual conditions can be determined with greater accuracy, consistently providing the optimum package size with the optimal tension without the need to do a roving test. In addition, the database itself is automatically updated based on actual

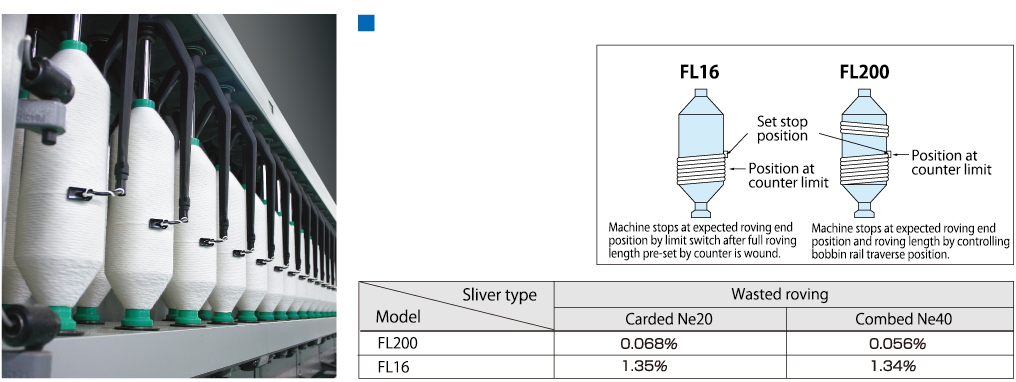

The FL200’s microcomputer control makes it possible to stop roving at both a fixed position and a specified length. The FL200 automatically returns to the set position once the length limit has been reached. Production yield improves because the length of the roving actually wound falls within ±1 meter of the specified length.