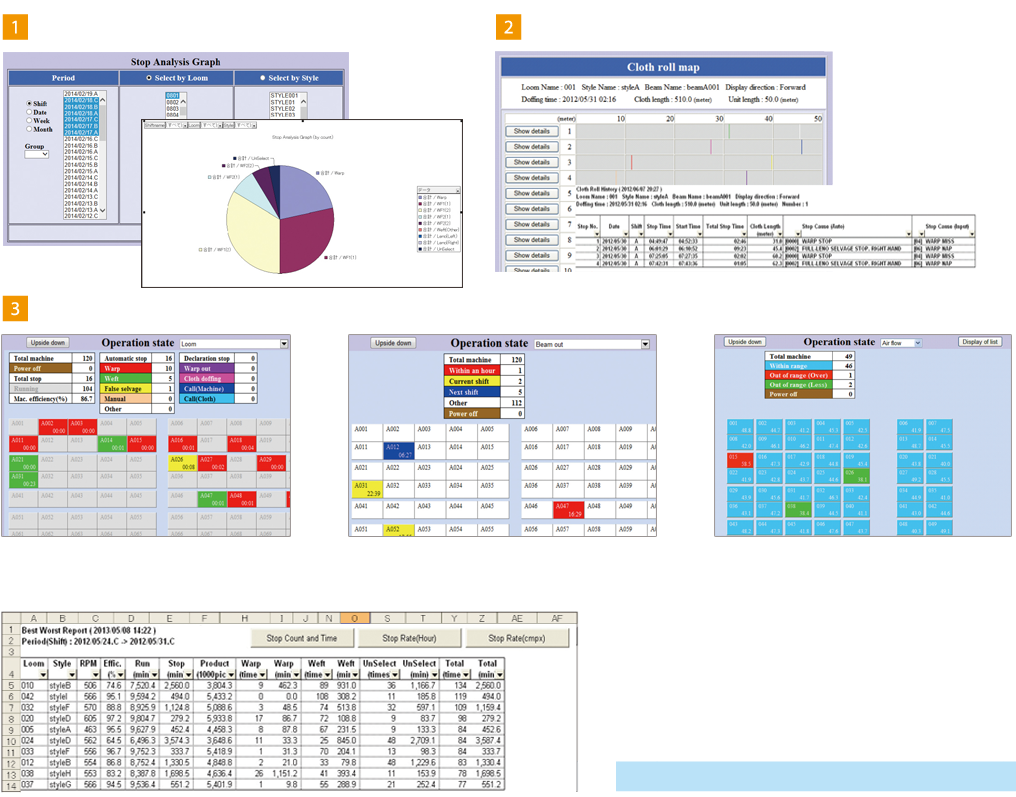

Toyota developed this new factory management system based on the Toyota Monitoring System (TMS), which was well received in the JAT710. Data such as shift reports and stop analysis graphs currently available can be displayed, as well as various breakouts showing operating status according to actual factory layout.

Uses a roll map to show stoppage location and the cause of the stop. This boosts the efficiency of the inspection process.

Operation Monitor ModeGives easy-to-see operating conditions according to actual factory layout.

Doffing/Warp Out Forecast ModePredicts which looms will require cloth doffing and which will have warp out within the next hour.

Air Consumption ModeLooms with abnormal air consumption are shown in red.

Best/Worst ReportAutomatically displays the 10 best and 10 worst looms in terms of capacity utilization and number of stops. Can be used for deploying setting conditions across all looms for optimal operation.

TMS (Toyota Monitoring System) will continue to be available.

*

Option

Option