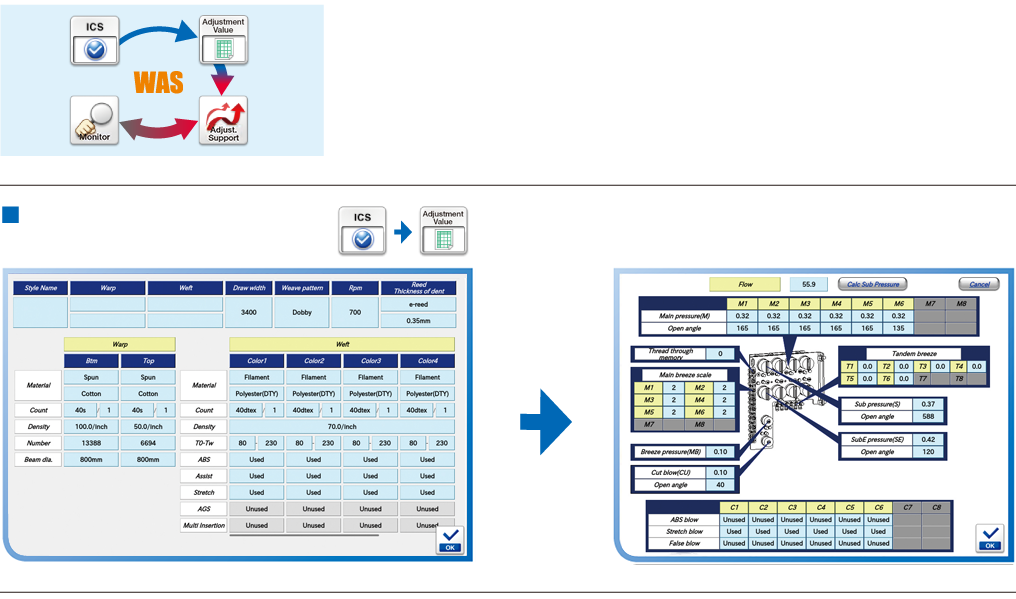

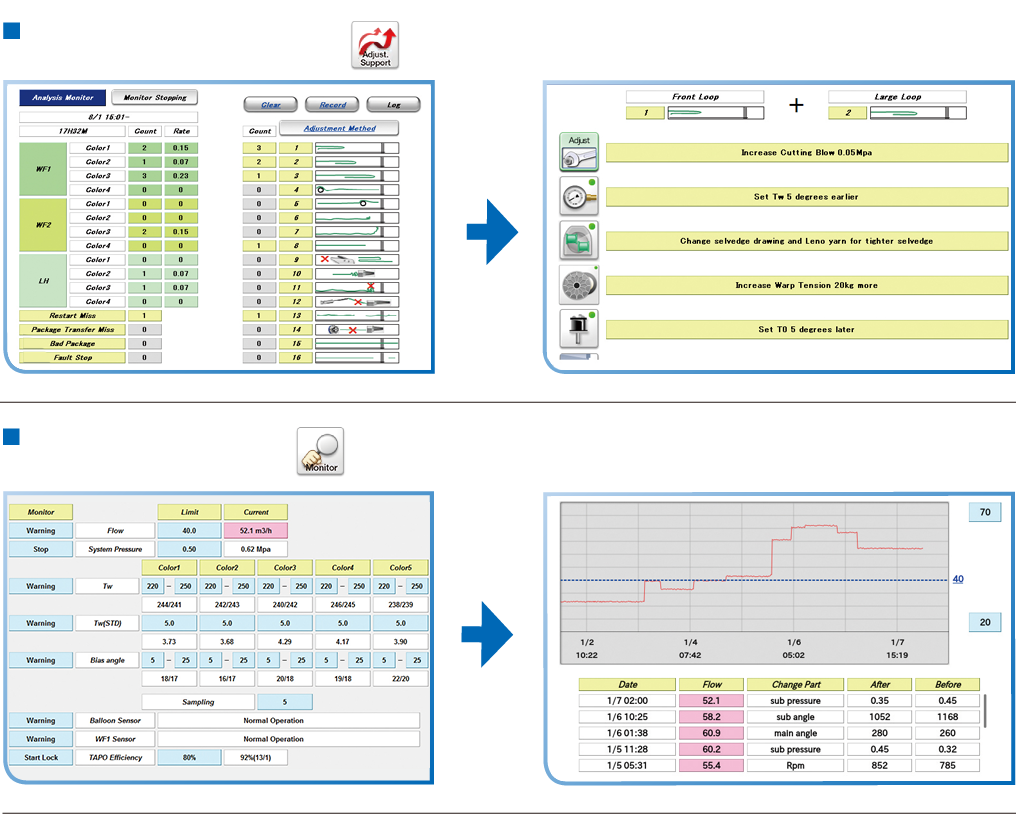

In addition to existing functions (ICS settings, electrical and mechanical parameters) that enable the optimum weaving conditions to be set automatically simply by selecting the fabric parameters, a newly designed Adjustment Support function assists the operator, for example, in making adjustments to reduce stop marks and the number of faults. In addition, for quality control, WAS monitors the number of faults and abnormalities, such as excessive air consumption, and warns and shuts down the machine to prevent the occurrence of defects: this maintains a high level of textile quality. Total management is also possible in conjunction with FACT.

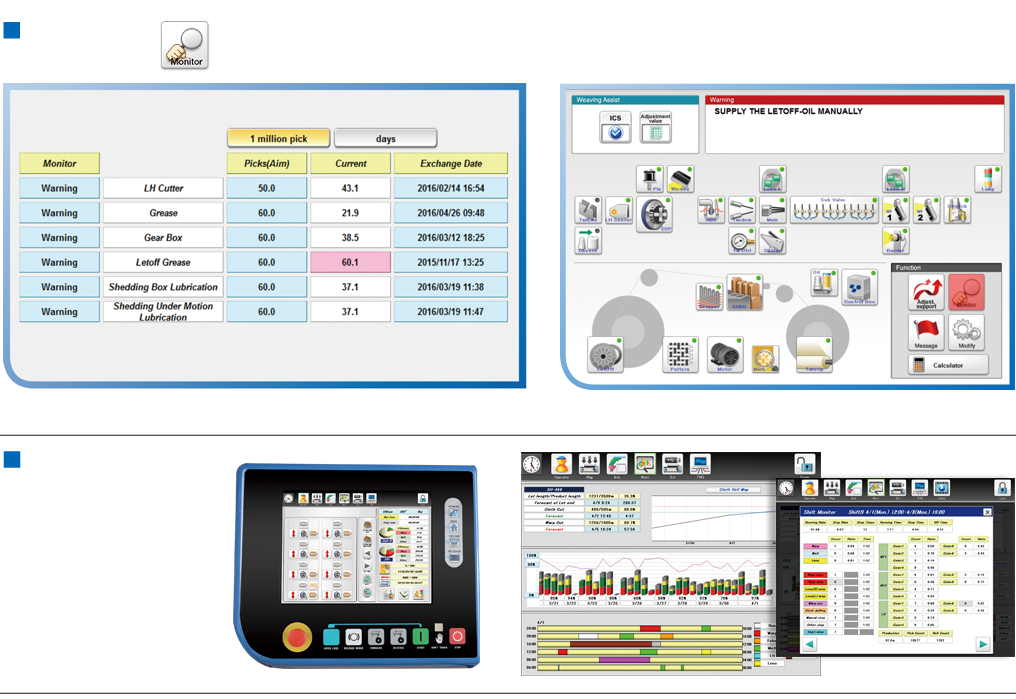

Alarm FunctionAlerts can be set for periodic maintenance.

The large panel operates with finger-swipe and finger-tap gestures, and provides simple, easy operability with a strong graphical presentation.

Lubricant is automatically supplied by designating a lubrication interval via the function panel.