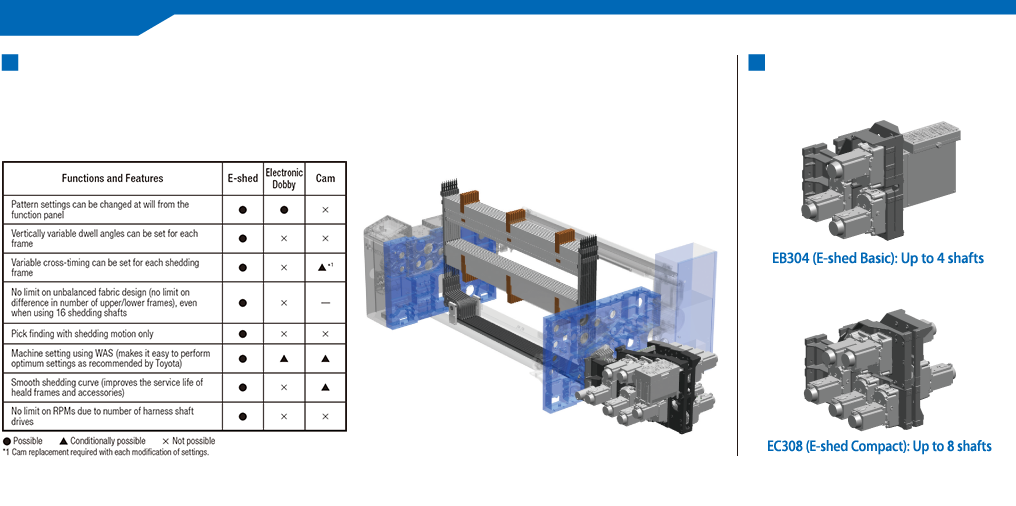

Independent servomotors drive individual heald frames. It is the ultimate shedding device with operability, as well as versatility, surpassing that of dobby units, and high-speed capabilities equal to or greater than cam shedding. The basic system has been newly redesigned for the third generation of this device, and high-performance motors and servo controllers were newly developed in-house for this shedding motion. Fabrics that had been highly challenging to weave can now be woven at high speed.

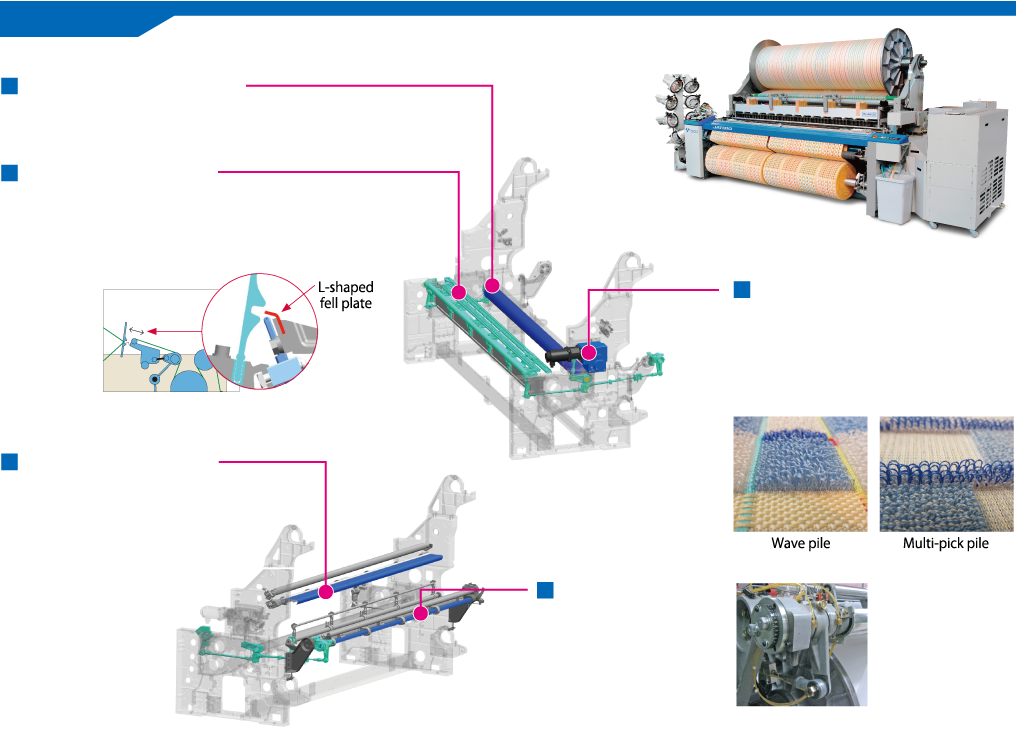

The cloth fell movement system is supported on the high-rigidity main shaft to prevent horizontal twisting and provide uniformly high-quality pile formation.

An L-shaped fell plate prevents interference between the sub nozzles and the piles. This cloth movement system synchronizes the fell plate with the terry motion to eliminate the adverse effect of the pile stroke.

Use of continuous leaf spring easing eliminates pile yarn rolling for high-speed operation and consistently high quality.

Originally developed for terry machines. Pile length and the number of pick piles (3 to 9 picks) can be specified as desired, and optimized servomotor control can handle a wide variety of designs at high speeds.

A torsion-bar system makes high-speed operation possible by improving tracking characteristics for ground let-off.