Mark

Auto leveling

pick finder

Selectable main motor start-up method*

Selectable machine stop/start angle*

Selectable start-up fabric movement*

Let-Off Adjustment*

Stoppage cause/timer

Kickback

Fell forward*

Color function

panel

Take-up adjustment

Stoppage cause/timer

Fell back

Main CPU

Drive

shedding

Load cell

Take-up

servomotor

Encoder

Let-off servomotor

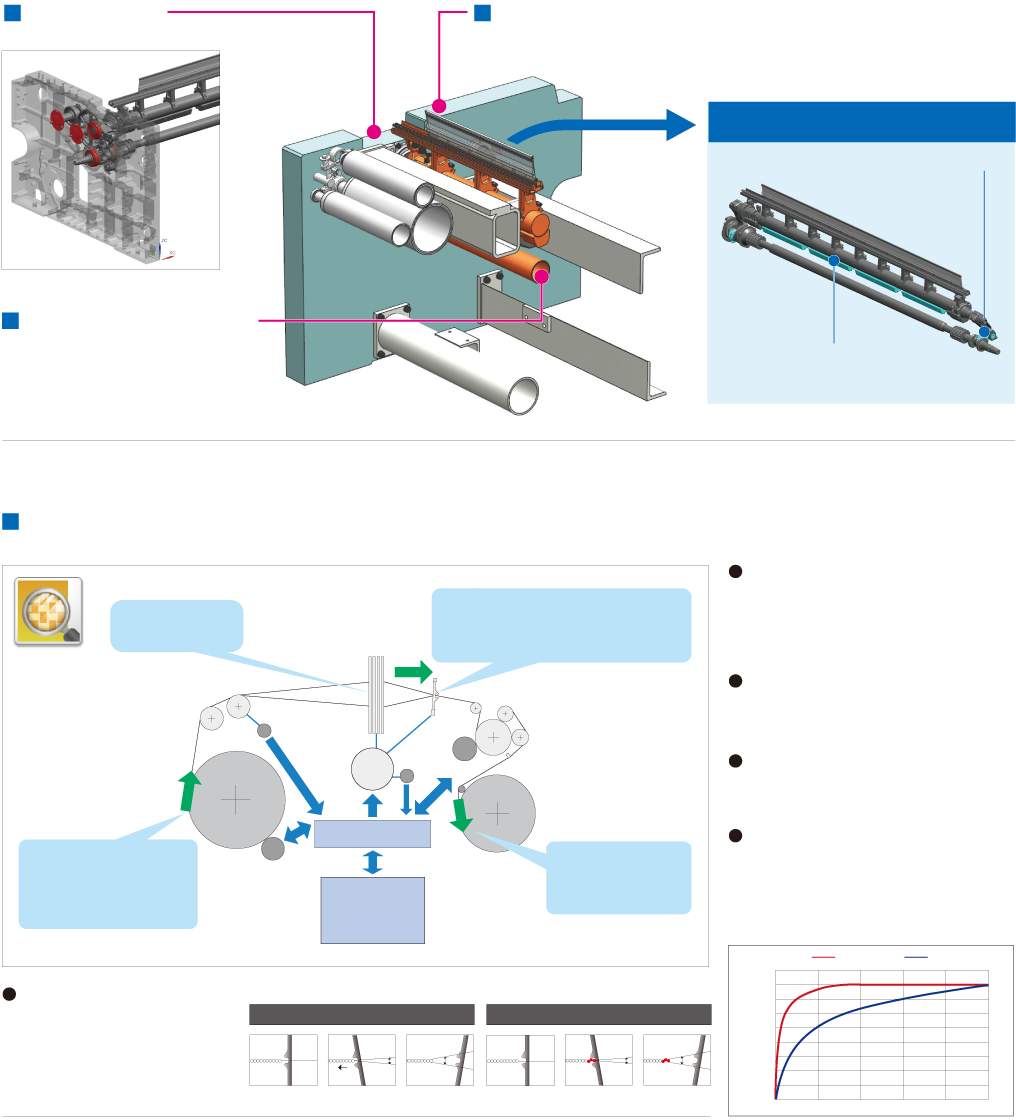

Selectable Start-Up Fabric Movement

Let-Off Adjustment

Selectable Machine Stop/Start Angle

Selectable Main Motor Start-Up Method

Fell Forward

Stop position

Slow backward motion

Stop position

Slow backward motion

Revolutions (rpm)

Delta start-up

Star start-up

Start-up characteristics

Time

Improved reliability of gearing parts

Robust frame structure ensures stable operation

Higher rigidity reduces vibration

Powerful CPU provides synchronous control of various devices, including let-off and take-up mechanisms. Various stop-marks including heavy or light-filling bar defects and wavy set marks can be prevented.

The operator can select a predetermined amount (mm) of reverse/forward let-off and take-up movement at start-up, effectively preventing light-filling bar defects (especially in temple areas). Note: The amount of movement and number of cycles are selectable.

The operator can arbitrarily set the amount of let-off permitted in response to stoppages or machine downtime, thus reliably preventing stop-marks.

The operator can prevent stop-marks by setting any arbitrary start/stop angle desired according to the type of fabric.

The JAT810’s super-fast start-up motor ensures full beating power from the first pick. Either a delta or star configuration can be selected for motor start-up, offering different start-up torques to prevent heavy or light-filling bar defects.

Releasing warp yarn let-off tension immediately after the loom halts prevents the cloth fell from touching the reed, thus eliminating another cause of stop-marks. After the loom restarts, the preset tension is automatically restored, and beating resumes at the normal cloth fell position.

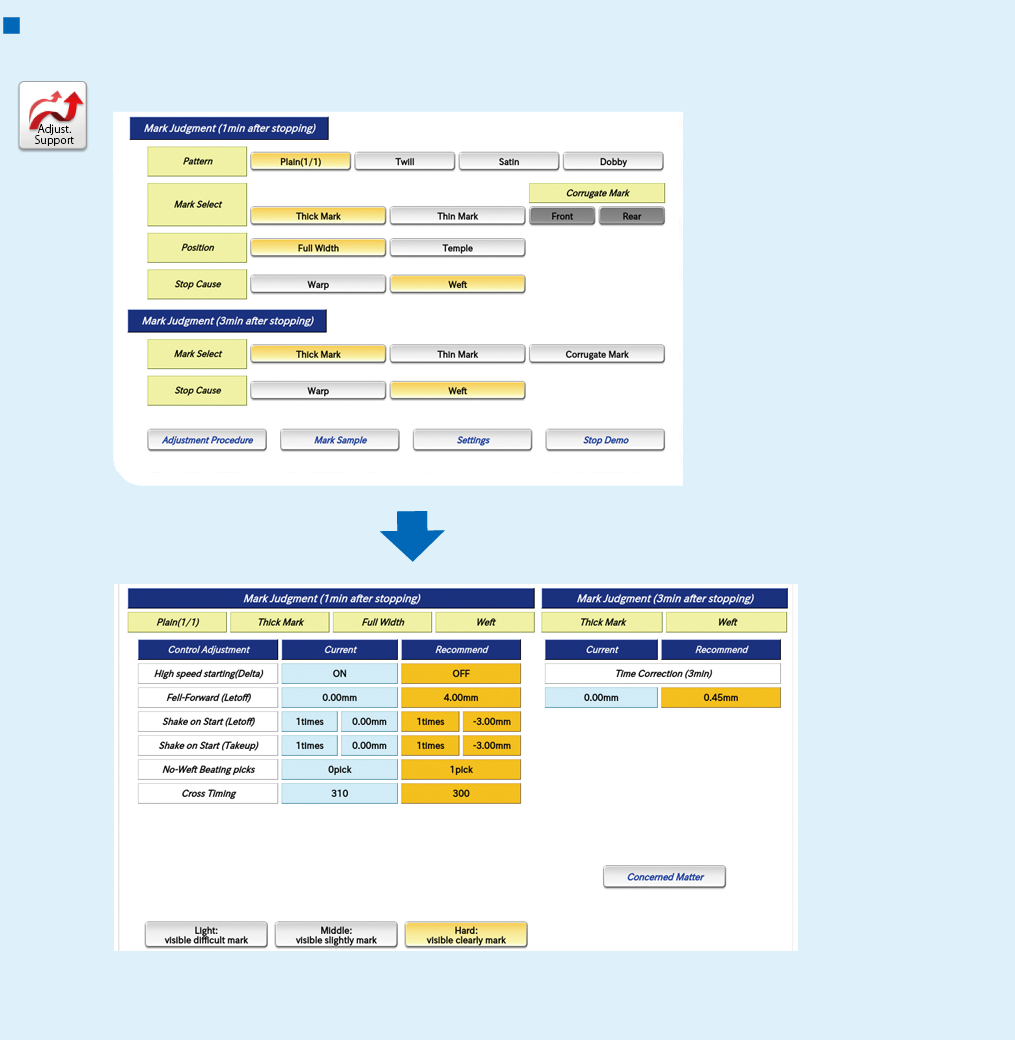

The JAT810 features a new stop-mark adjustment function via WAS.

Analyzes stop-mark conditions

Shows corrective actions