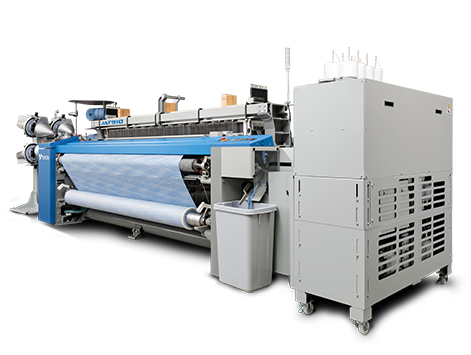

Toyota's FACT (FACTory Management System) is a factory management support system that was introduced with the JAT810 model to maximize the efficiency of the weaving process. This system has evolved with the JAT910 into "FACT-plus" with improved factory automation functions. FACT-plus support the smooth factory operation by making optimal proposals to "Machines" and "Operators", and facilitating cooperation with existing factory management systems.

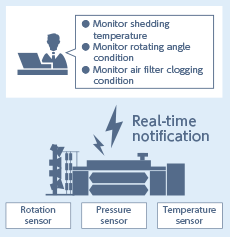

Various sensors collect data from machines in real time, visualizes changes in machine condition, and uses this information to plan maintenance.

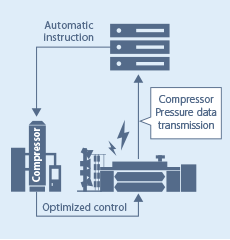

Real-time monitoring of the air pressure requirements at the machine and automatic optimal control of the compressor pressure settings will reduce power consumption.

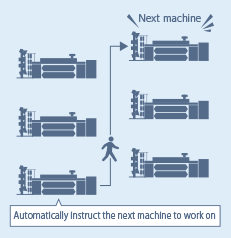

By monitoring the factory operation status in real time and automatically instructing the next machine using Toyota's original algorithm, we aim to further improve the efficiency of the entire factory.

By further analyzing and visualizing the "waiting time" and "repair time" of the machine stand stop time, we aim to improve proficiency and optimally allocate factory personnel.

By linking with the preparation-process data (fabric style, beam details, machine table, etc.) in the existing factory management system, the machine settings can be set efficiently and weaving conditions can be optimized. In addition, the data can also be used as cloth data used for tracing in the customer's inspection-process.