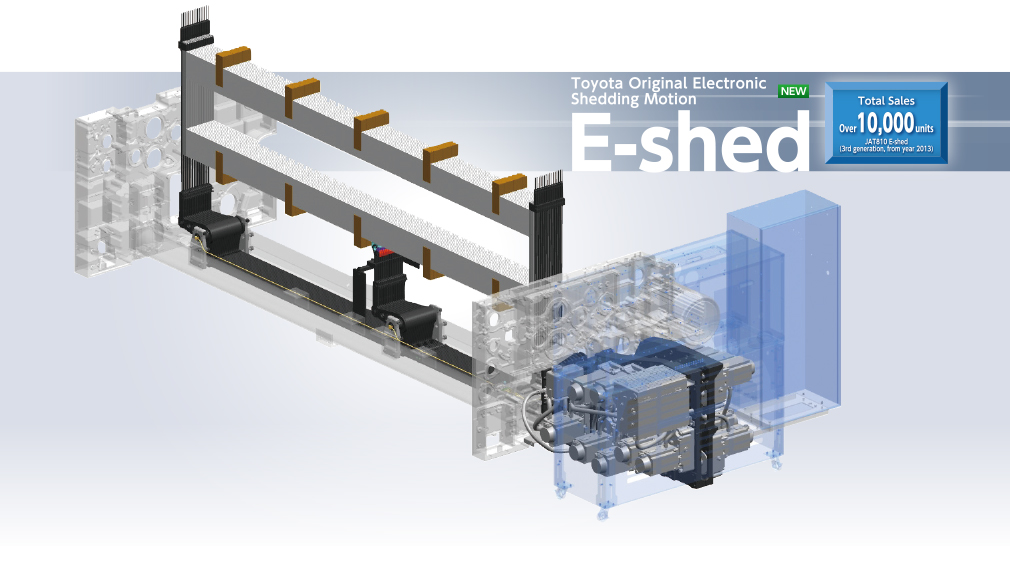

Toyota's original E-shed technology has evolved since its launch in 2000. The 4th generation E-shed model offers further energy savings by optimizing the shedding control movement and introduces a new function that allows the customer to weave challenging fabrics at high speed.

The E-shed drive system individually controls each heald frame by the use of a servo motor. It is the superior shedding motion technology that offers higher productivity and versatility than Cam or Dobby shedding motions.

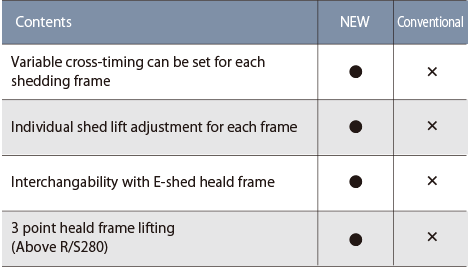

E-shed Function and Features

● : Possible ▲ : Conditionally possible × : Not possible

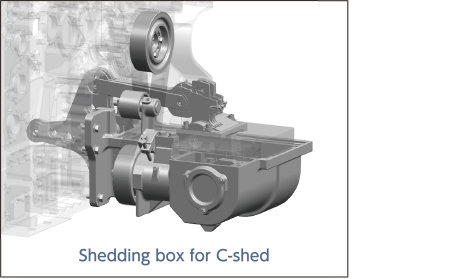

The newly developed Multi-link and Simple-link crank shedding systems with E-shed technology provide improved productivity, enhanced weavability, and reduced maintenance requirements.

C-shed Function and Features

● : Possible × : Not possible

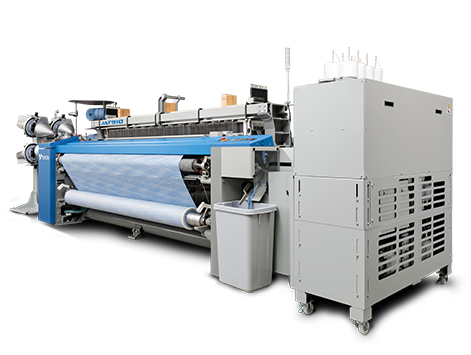

Based on the basic principles and performance of the JAT810, the newly designed pile motion and tension control mechanism achieve high productivity and superior quality with a varieties of styling from gauze towels to bath mats that will satisfy all customer needs.

Newly improved linkage mechanism and pile motion control system including pile motion motor which allows a wider variety of styling at higher speeds.

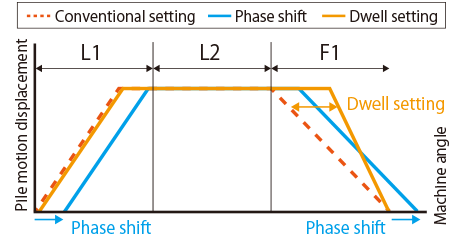

The newly desiged pile motion control allows for more detailed and flexible movement. Detailed parameters for a variety of styles improve pile alignment and prevent pile pulling.

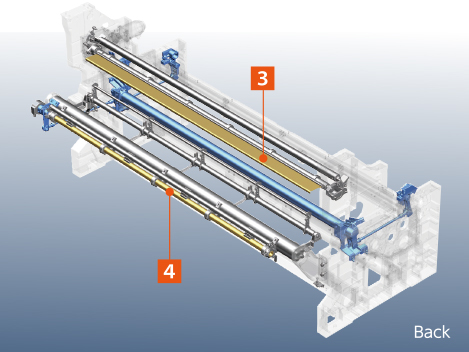

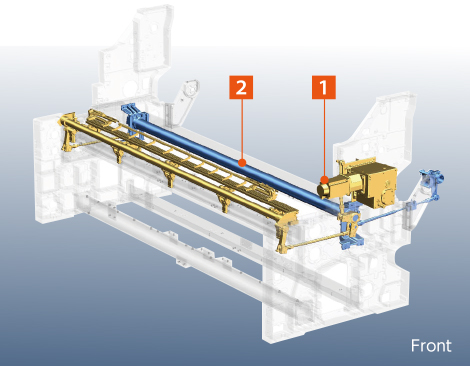

The cloth fell movement system which is supported by the high rigidity main shafts prevent horizontal twisting and provide uniform high-quality pile motion.

Use of continuous leaf spring easing eliminates pile yarn rolling for high-speed operation with consistent high quality.

A torsion-bar system makes high-speed operation possible by improving tracking characteristics for ground let-off.