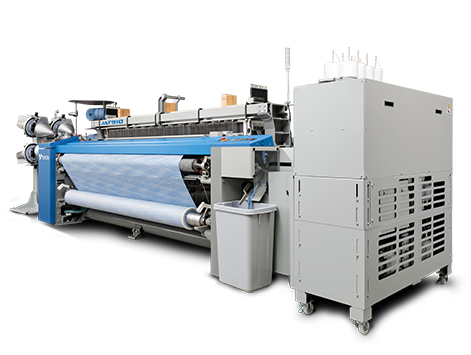

The JAT series boasts a high level of performance factors for basic operations. Inheriting that gene, the JAT910 has further evolved achieving remarkable power reduction, improved speeds, while lowering vibration levels. This was accomplished by improving the performance of the main motor and optimizing the loom design. Advancements were also made in the stop mark prevention system to provide customers with the highest reliability.

By adopting a high-efficiency motor and renewing the control method, further power reduction and strengthening of the stop mark prevention function can be accomplished.

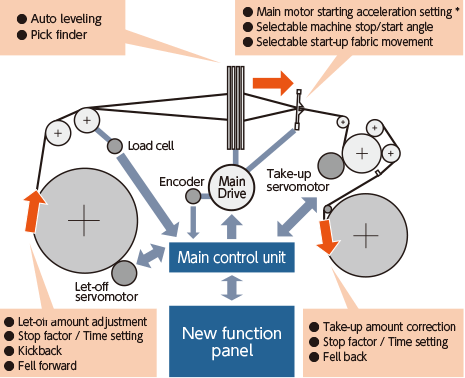

Performance response has improved by increasing the function panel CPU processing speed. This improvement collaborating with FACT, has expanded further technological possiblities.

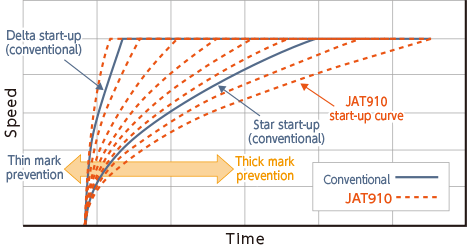

Evolved Stop Mark Prevention System

The main control CPU, with significant improvements, provides synchronous controls of various devices including the let-off and take-up systems. With these improvements, various cases of stop marks can be prevented.

The new main motor allows multi-step setting of starting acceleration. It greatly contributes to the prevention of stop marks such as thick or thin marks.

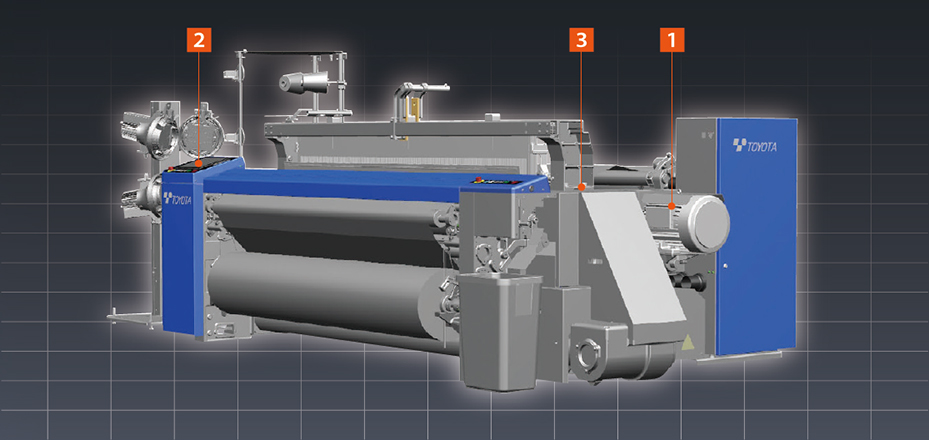

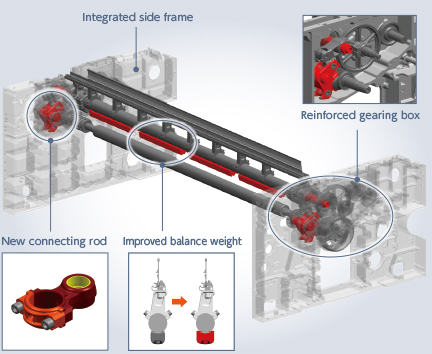

By strengthening the gearing/beating mechanisms and optimizing the loom side frame design, higher speeds and lower vibration can be achieved.

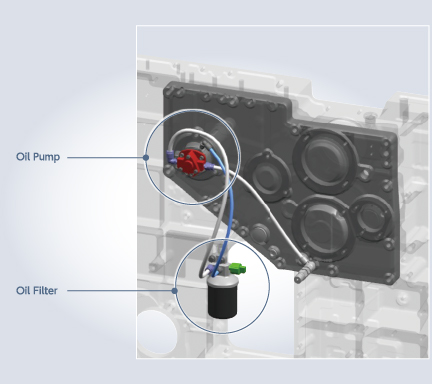

The oil pump and filters are integrated with the gearing box to remove contaminants, helping extend the life of the bearings and other internal components.