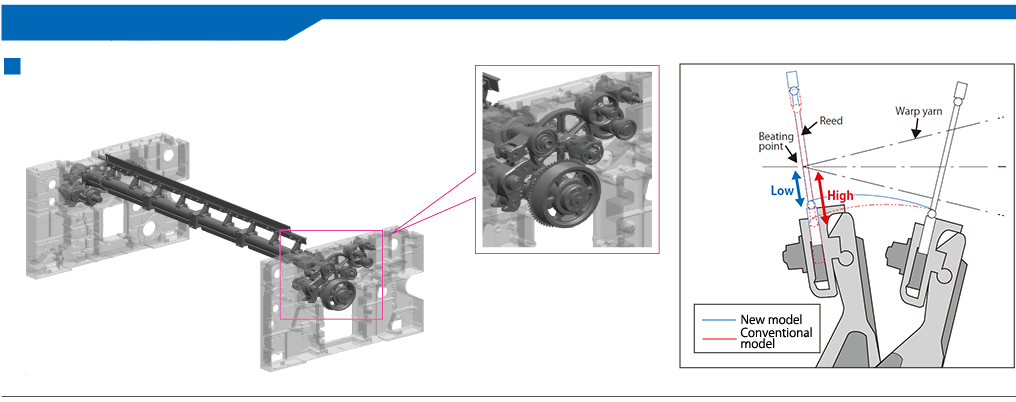

The newly designed Beating Motion provides a 50% reduction of machine vibration through the use of lighter weight materials, hardened beating related components, and applying balance weights across the full width of the machine.

Enhanced beating motion can achieve higher versatility weaving for high-quality textiles.

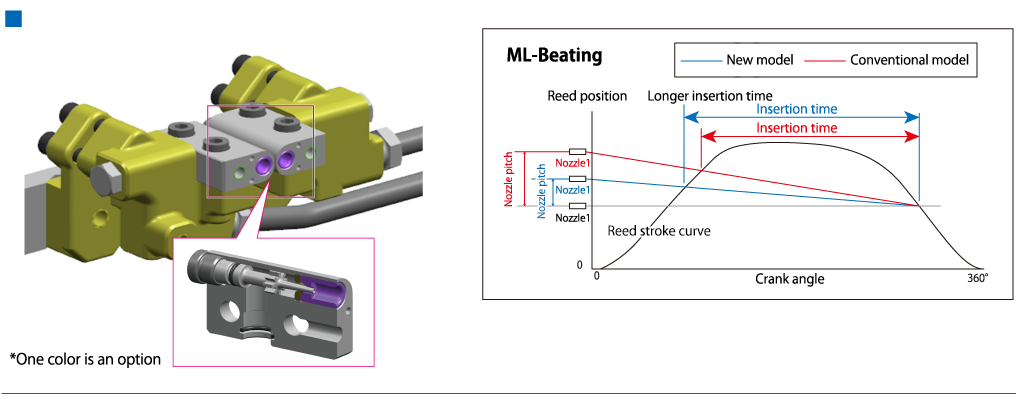

Micronozzle

Our newly improved ML Beating curve allows an increased weft insertion time for reliable operation. In addition, the combination of a micro nozzle can provide a higher level of operation.

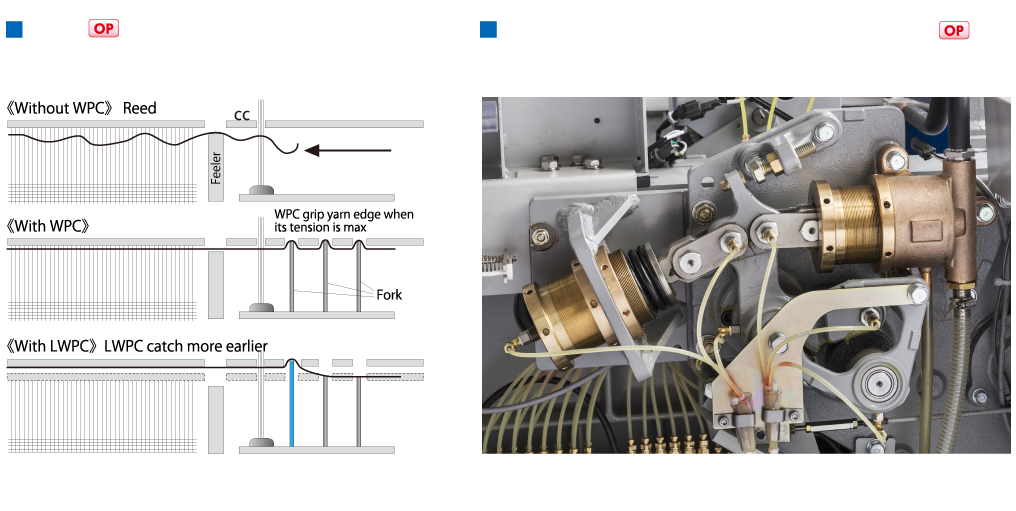

LWPC grip yarn edge earlier makes a uniform weft yarn tension and improves fabric quality.

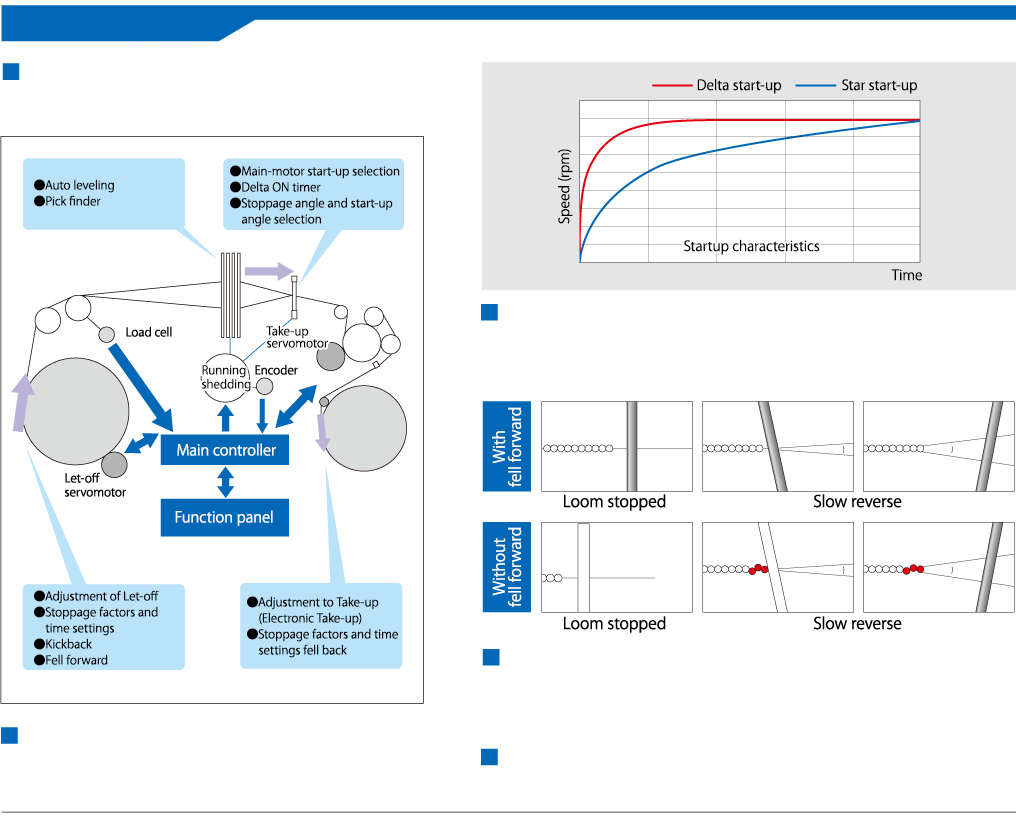

The powerful CPU controls many devices, including let-off and take-up mechanisms, effectively preventing stop marks.

The super-fast start-up motor ensures full beating power from the first pick. Either a delta or star configuration can be selected for motor start-up, offering different start-up torques to prevent heavy or light filling bar defects.

The operator can set the amount of let-off permitted as needed in response to machine stoppages or downtime, thus reliably preventing stop marks.

Releasing warp yarn tension immediately after the loom stops prevents the cloth fell from touching the reed, thus eliminating a cause of stop marks. When the loom is restored, the beating resumes at the normal cloth fell position.

The stoppage angle and start-up angle can be selected to match the type of fabric and prevent stop marks.

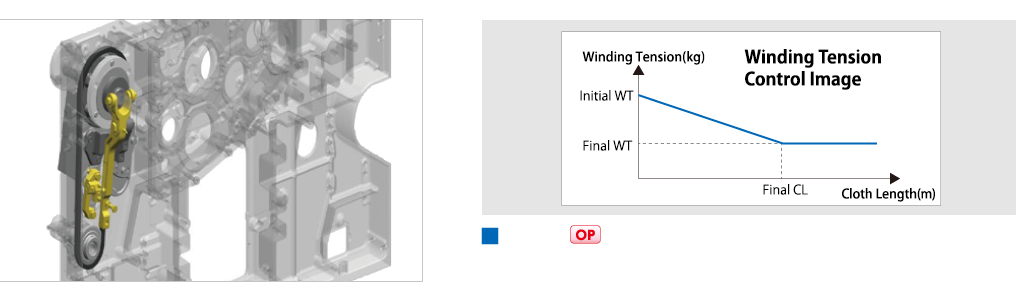

A wide range of winding tension is settable by motor control. It helps reduce wrinkles which improves the overall quality of cloth.

*

Option

Option