Original suction type compact with high performance and yarn quality

New model with enhanced versatility in addition to the functions of the EST3

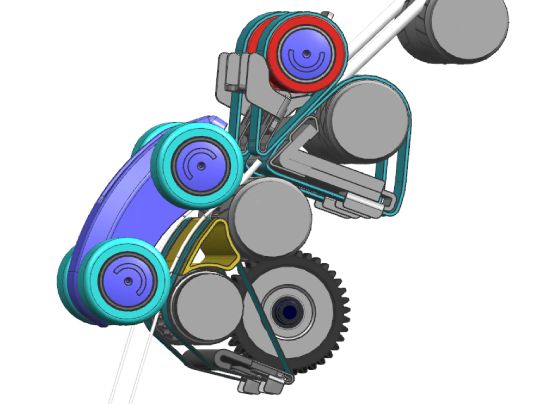

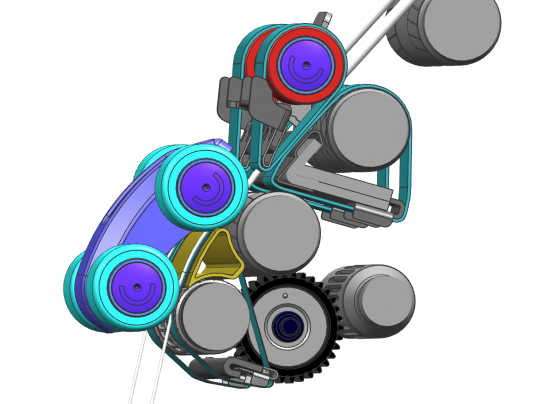

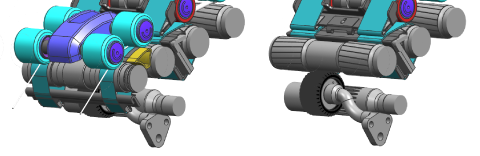

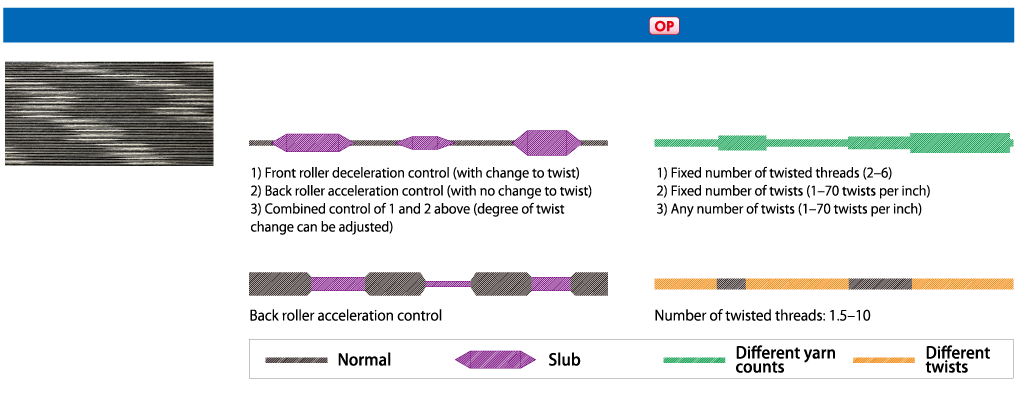

Many types of fancy yarns can be handled such as slub, multi-count, and multi-twist ones. High-response servo motors drive all three bottom rollers. This makes it possible to not only slow down the front roller, but also speed up the back roller. In addition, the supplied software makes it easy to record and manage pattern simulation and settings data.

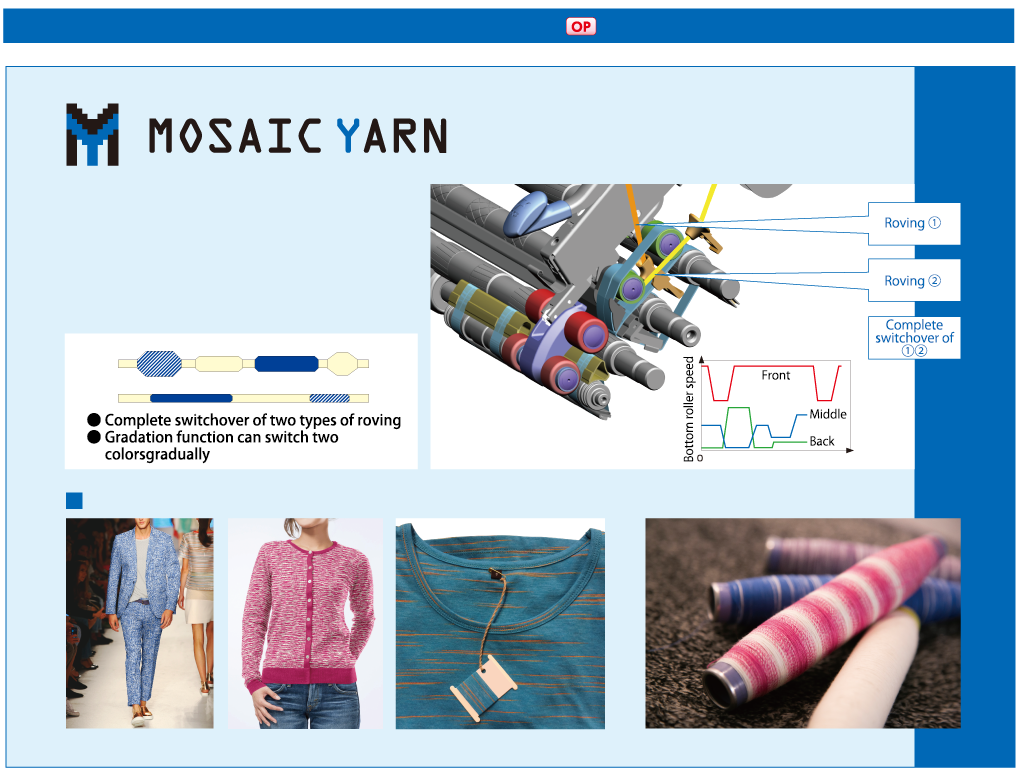

The new MOSAIC® e-draft spinning device, which is capable of spinning injection slub yarn mixed with colored roving sliver, has the ability to produce yarns with a variety of fabric densities, yarn shapes, and slub size. This process is accomplished by combining different types of raw cotton and roving materials. Unlike conventional spinning technology that twists and drafts, this new technology “detaches and attaches” roving sliver. This concept is a totally new innovation that has never been introduced in the spinning industry.

*

Option

Option